Do you have a cold room or freezer room?

Advantages

Why do you benefit from air curtains?

Engergy saving

Significant reduction of electricity costs by stopping the waste of expensive cold air.

Ice free freezing room

No hoarfrost at refrigerated goods, no ice accumulation at the ceiling, floor and evaporator.

Hygienic correct

Fulfills all hygienic requirements of the food industry.

Protecting the goods

There is no incorrect increase of the temperature in the freezing room and your goods are reliably protected.

A comfortable transport of goods ensures a smooth operating procedure

Goods can be transported comfortably through the free door opening

A longer lifetime of the cooling machines

The cooling machines have a longer life, because they no longer need to run unnecessarily to cool the warm air penetrated through open cold store doors.

Mosquito stop

Doors with air curtains detain mosquitoes and flying insects to enter.

No risk of damage

Air curtains cannot be damaged. They are installed above the door, so that they are out of the working area of forklifts.

The investment pays off quickly

Return of investment within one or two years.

Technology

How do air curtains work?

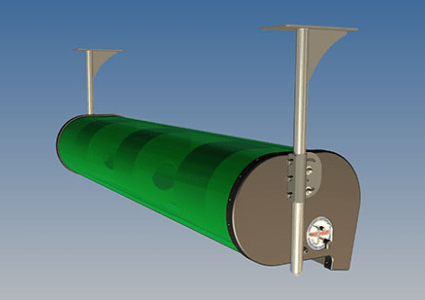

A door of moving air.

An air curtain system is a device that prevents an exchange of air through a wall opening, without any physical barrier.

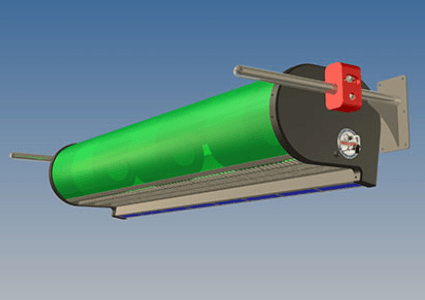

There is an air curtain blower with an air collection box and a discharge nozzle. A door out of moving air. The systems are equipped with a particular air rectifier in the outlet nozzle. There are hundreds of small blowpipes.

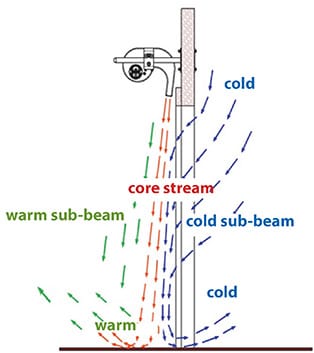

The air flow generated by the radial fans is directed through the blow tube rectifier. It is completely laminar, homogeneous and free of turbulence. The beam is narrow and extends far. This jet of air is blown at right angles to the inflowing air, or surrounding. The air jet must be so strong that it reaches to the floor and tears the incoming or adjacent air with it.

Without air curtain

fig.1

Open door without air curtain

Opening the door of a coldroom or freezing room causes an air flow of cold and heavy air outside at the ground level, while you have an infiltration of warm air above.

With air curtain

fig. 2

Open door with air curtain

FRIGOVENT air curtains create an unique air barrier, in order to avoid, that cold air can escape and warm air can infiltrate the cold storage or freezing room.

Core beam and sub-beams

Core beam and sub-beams

at the correct setting.

Special features

What characterizes FRIGOVENT air door systems?

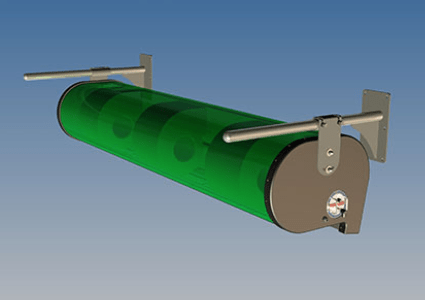

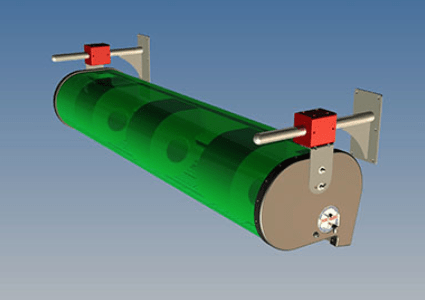

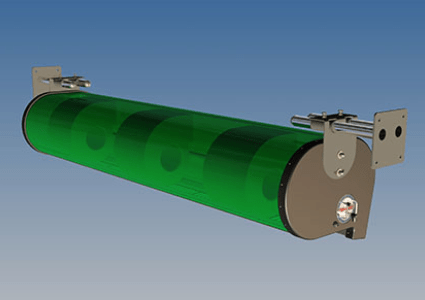

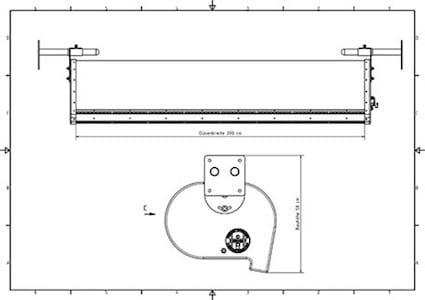

The housing of the air curtain system can be mounted cantilevered over a distance up to 8 meters. During assembly, the system is placed on two brackets, which are mounted next to the door opening. On the brackets, the air curtains can be pushed in an optimal position to the door ope-

ning. So the Thermovent is particulary suitable for extra-wide door openings with overhead doors, sliding gates and rolling doors. These doors can move freely behind the air curtain system.

We use energy saving fans of ebmpapst – made in Germany. These blowers are equipped with electronically commutated DC motors.

The ebmpapst EC motors are the result of a very complex development. These motors work with an extremely low power consumption.

They are very simple and very suitable for continuous operation and characterized by a very low operating noise.

The power consumption at full load is only half as high as of normal motors.

With our FRIGOVENT air curtains, the speed is regulated down.

Then the power consumption falls further analogous to the speed.

Whenever the door is opened, a proximity switch activates the air curtain just when the door is removed from the switch. So the fans are already powered up when the door is fully opened. This is a special switch. It is completely sealed without any moving parts. It is totally waterproofed and works with an operating current of only 24 volts. It is a security switch, which cannot cause any electrical accidents.

Thermovent air curtains can be installed on the warm or cold side of the wall above the door. We suggest the installation on the warm side.

The blowers draw in warm air from the higher indoor range and blow it through the outlet nozzle with the air rectifier down. This rectifier is made out of hundreds of small blowpipes. In this way a turbulence-free particularly homogeneous air stream is

generated. The air stream is sufficient with the large Thermovent FLS to reach eight meter far to the ground. Heating of the air stream for a good function is not neccessary.

The system is controlled electronically. There is a slide-in control with the electronics and all critical components, such as:

- The control of the fan speed

- The circuit of the fan by contactless relays

- The generation of the safety current – 24 Volt DC – for the proximity switch

- The waterproof connector for this switch

In case of failure, this slide-in control can be pulled by the operator and exchanged with a new one quickly. This eliminates time-consuming troubleshooting and quick repair.

So a global fast service is available.

Assembly

Assembly variants of the air curtains

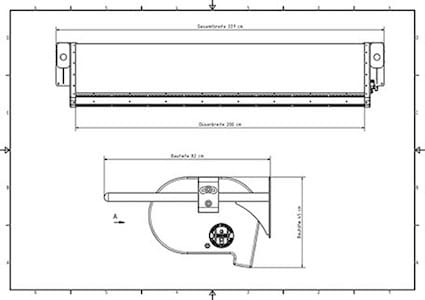

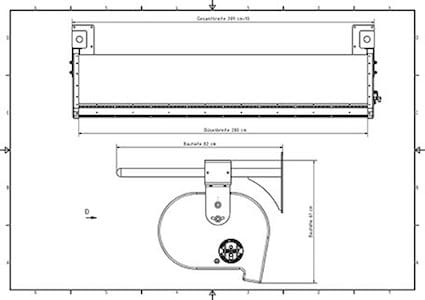

Rear wall assembly with normal construction width

The FRIGOVENT will be mounted with two stainless steel panels with solid polyamide blocks on the warm side of the wall above the door opening. This is the normal type of installation.

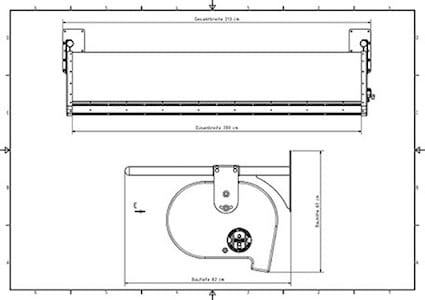

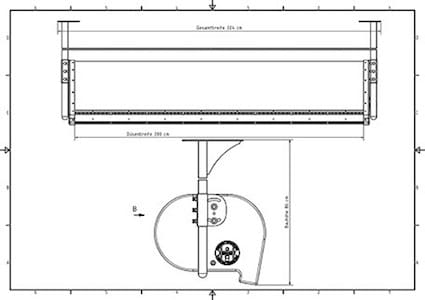

Rear wall assembly with reduction of the construction width

The FRIGOVENT will be mounted with two stainless steel brackets on the wall above the door opening.

These consoles take up less space in the construction width – but need more space in the height.

Rear wall assembly with variable console distance

The FRIGOVENT is mounted with two stainless steel brackets with solid polyamide blocks on the warm side of the wall above the door opening. If you can not mount the brackets in the right distance, it can be corrected by shifting the angle brackets below the polyamide blocks.

Ceiling mounting with mounting under the ceiling

The FRIGOVENT will be mounted with two stainless steel brackets under the ceiling above the door opening.

Side mounting with mounting on the side walls

The FRIGOVENT will be mounted with two stainless steel panels with polyamide solid plates on the side walls and in front of the door opening. This type of installation is often used in corridors that are sealed off by air curtains against cold air loss.

Download

Catalog FRIGOVENT air curtains

An 24-page booklet that shows the use of air curtain units of cold room and freezer room doors. On a calculation example, the significant cost savings shown that is possible through the use of these facilities.

An overview of the offer, which includes 42 air curtains.

There are facilities for small cold store doors with a single pass measurement of 100 x 200 cm up to large sliding doors 600 x 350 cm.

Contact

Order directly from us

* required

FRIGOQUIP GmbH

Mon. – Fri.: 7:00 – 16:00

Directly to the right contact person

Pietro Mattana

Administration air curtain

Germany/Austria/Switzerland