Would you like to seal up your factory door comfortably?

Advantages

Why do you benefit of THERMOVENT air curtains?

Energy savings

Significant reduction in heating costs by avoiding warm air losses at open gates.

Smooth operation by unhindered transport of goods

Convenient and fast, the goods can be transported through the free door opening. Swing doors and strip curtains are no longer necessary.

Hygienically safe

All hygiene requirements of the food industry are met. Contamination of the products by swinging doors or strip curtains is impossible.

Accident prevention

See and be seen is made sure. A dangerous free movement of goods through the air curtain is always guaranteed. Unrestricted view.

Protection against insects

No ingress of insects through doors, which are protected by air curtains. The inflow of dust and smoke is reliably prevented.

Longevity

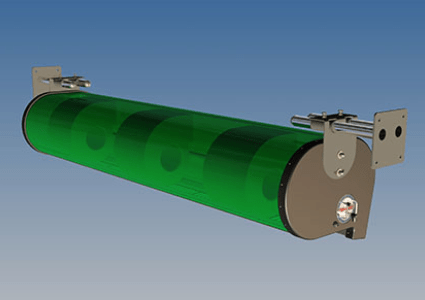

The THERMOVENT air curtain system is located above the door and out of the transport area and cannot be damaged by fork lifts mechanically.

Technology

How do air curtains work?

A door of moving air.

An air curtain system is a device that prevents an exchange of air through a wall opening, without any physical barrier.

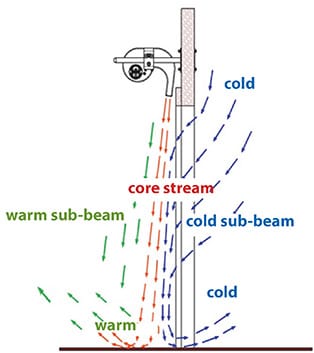

There is an air curtain blower with an air collection box and a discharge nozzle. A door out of moving air. The systems are equipped with a particular air rectifier in the outlet nozzle. There are hundreds of small blowpipes.

The air flow generated by the radial fans is directed through the blow tube rectifier. It is completely laminar, homogeneous and free of turbulence. The beam is narrow and extends far. This jet of air is blown at right angles to the inflowing air, or surrounding. The air jet must be so strong that it reaches to the floor and tears the incoming or adjacent air with it.

Without air curtain

fig.1

Open door without air curtain

If you open a door of a warehouse or factory gate, cold and heavy air from the outside penetrates at the lower part of the door opening. Warm air escapes to the outside at the upper part of the door.

With air curtain

fig. 2

Open door with air curtain

Thermovent air curtains create an unique air barrier, in order to avoid, that warm air escapes and cold air infiltrates in the building.

Core beam and sub-beams

Core beam and sub-beams

at the correct setting.

Special features

What characterizes THERMOVENT air door systems?

The system is controlled electronically.

There is a slide-in control with the electronics and all critical components, such as:

- The control of the fan speed.

- The circuit of the fan by contactless relays.

- The generation of the safety current –

24 Volt DC – for the proximity switch. - The waterproof connector for this switch.

In case of failure, this slide-in control can be pulled by the operator and exchanged with a new one quickly. This eliminates time-consuming troubleshooting and allows a quick repair. So a global fast service is available.

Assembly

Assembly variants

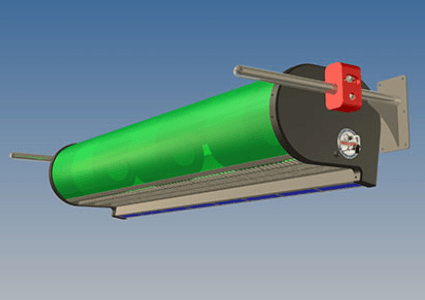

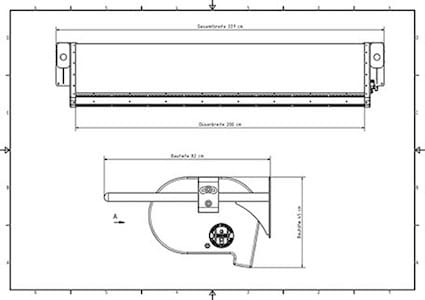

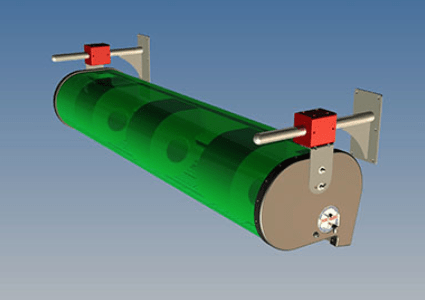

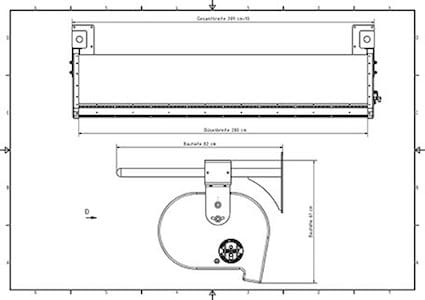

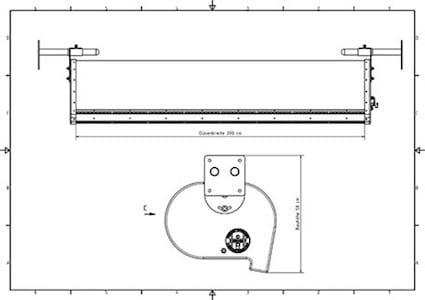

Rear wall assembly with normal construction width

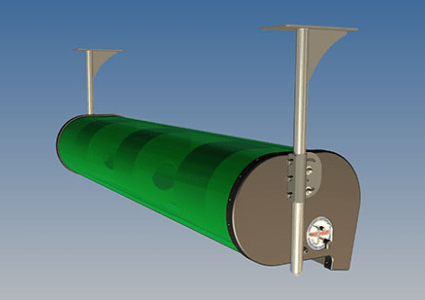

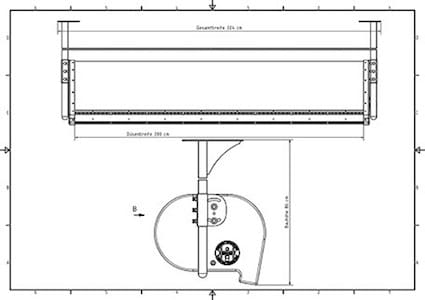

Rear wall assembly with reduction of the construction width

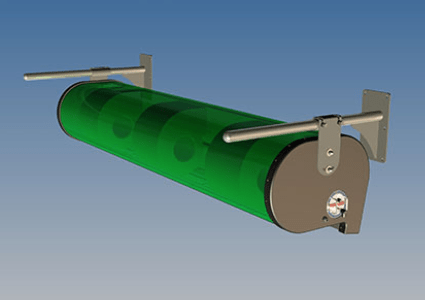

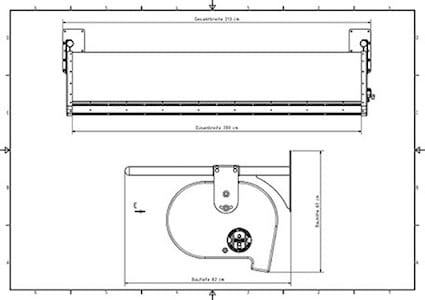

Rear wall assembly with variable console distance

Ceiling mounting with mounting under the ceiling

Side mounting with mounting on the side walls

Download

Catalog air curtain systems for factory doors

THERMOVENT air curtain systems for door heights up to 800 cm

An 24-page booklet that shows the use of THERMOVENT air curtain units of warehouse doors and factory gates. On a calculation example, the significant cost savings shown that is possible through the use of these facilities.

Facilities are available for door heights up to 8 meters and door widths up to 6 meters.

Contact

Order directly from us

* required

FRIGOQUIP GmbH

Mon. – Fri.: 7:00 – 16:00

Directly to the right contact person

Pietro Mattana

Administration air curtain

Germany/Austria/Switzerland